At AES, we tend to talk about the technology behind our modular cleanroom installations—and for good reason. Our cleanroom designs are informed by decades of practical experience, and we continually innovate our products to engineer leading solutions for our customers.

The very point of installing your cleanroom, however, is to commission and then validate that cleanroom so you can get to work manufacturing your vaccine or therapeutic. With AES Clean Technology Faciliflex Module cleanroom designs, successful commissioning and qualification comes standard.

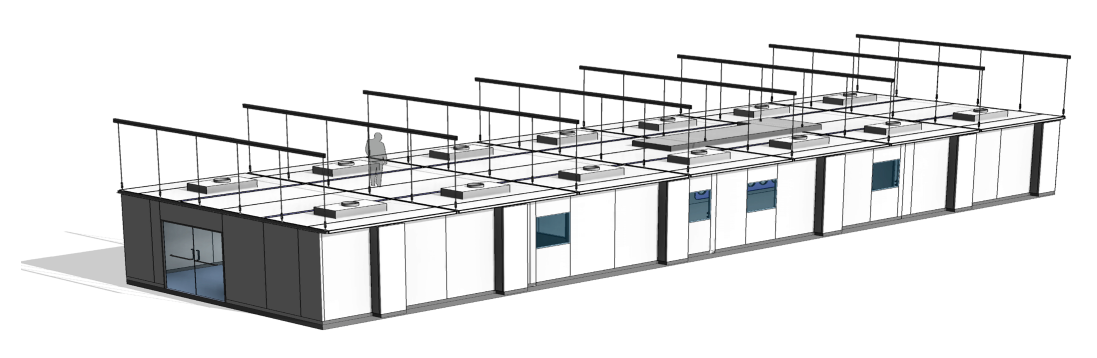

Our standardized modular cleanroom approach is why we say that we install cleanrooms—we don’t build cleanrooms. All the actual construction happens in our controlled manufacturing facilities, so that when the time comes to install Faciliflex components at your facility, there are few variables that could impede successful commissioning. Our proven cleanroom technologies and designs are a known quantity to customers and regulators alike.

This past year, we helped a half dozen or more clients design, install and commission their cleanrooms in record times. Operation Warp Speed provided grease to turn the great gears of manufacturing much faster than ever before—yet without a built-in plan for commissioning and qualification many of our customers could have otherwise found themselves simply spinning their wheels.

With both speed to market and lives in the balance, a lot of pressure will be brought to bear on your healthcare organization’s commissioning plan. We drive the process toward successful commissioning and qualification every step of the way—from our first meeting to the moment we hand over documentation.

How AES Simplifies Commissioning

Commissioning is the systemic and documented approach to verify that your cleanroom performs as designed and in accordance with your manufacturing needs. As I said, AES modular cleanroom designs are a known quantity—our designs take the guesswork out of the construction process as well as the mechanical engineering process. We know how all the parts will go together, and we guarantee their performance.

Of course, your commissioning plan is part of your overall manufacturing plan, whether you realize it or not. AES has modular cleanroom designs that fit any space and any need. The earlier we are part of your cleanroom design process, the more smoothly commissioning will commence.

Two main components of commissioning are the design installation and design qualification processes (IQ and DQ, respectively). The IQ simply means that everything is installed as we said they would be in the contract. It is with great satisfaction that I tell you that people rarely question our IQ at AES Clean Technology, especially as they see how quickly and cleanly our installations come together.

DQ, on the other hand, is a verification that the cleanroom is suitable to the task for which it has been designed. DQ is a measure of our ability to work with you to deliver a design that meets your expectations.

Our GDP Is Always On the Rise

At the heart of every commissioning and qualification is documentation—GDP or Good Documentation Practices. With AES cleanroom designs, however, we might as well call GDP “Good Design Promises,” since we maintain a comprehensive documentation library covering every aspect of every component in your cleanroom design build. With all of our cleanroom components engineered to exacting standards, developing the correct documentation for commissioning is as simple as matching your design to our library.

Proven modular cleanroom design plus an experienced installation team plus GDP equals a risk-free commissioning process with no surprises.

About Josh Russell

In 2019, Josh came to AES Clean Technology with over 15 years of engineering experience in aseptic manufacturing. As Vice President of Sales & Marketing, he leads multidisciplinary teams to deliver dependable cleanroom facilities to clients throughout the life sciences industry.