With Faciliflex Express, Tailored Cleanroom Design and Risk Reduction Become Standard

Last month, AES Clean Technology launched our Faciliflex Express offering, a complete cleanroom design package that can be installed in as little as six months. With Faciliflex Express, we have turned the lengthy, complex process of cleanroom design and cleanroom construction into a fully realized product, backed by decades of experience.

With more than 3,000 successful cleanroom design build projects, AES Clean Technology is North America’s first turn-key, prefabricated, flat-packed modular cleanroom supplier. Now, we are the only company that designs, manufactures, installs and commissions complete cleanrooms that can meet global regulatory and industry standards on day one.

Introducing the Third Generation of Cleanroom Design

The first cleanroom was introduced 60 years ago, when each new facility was built individually—engineered from the ground up at great expense and unproven results. This “Design Build” process was state of the art then, and it met the needs of the time.

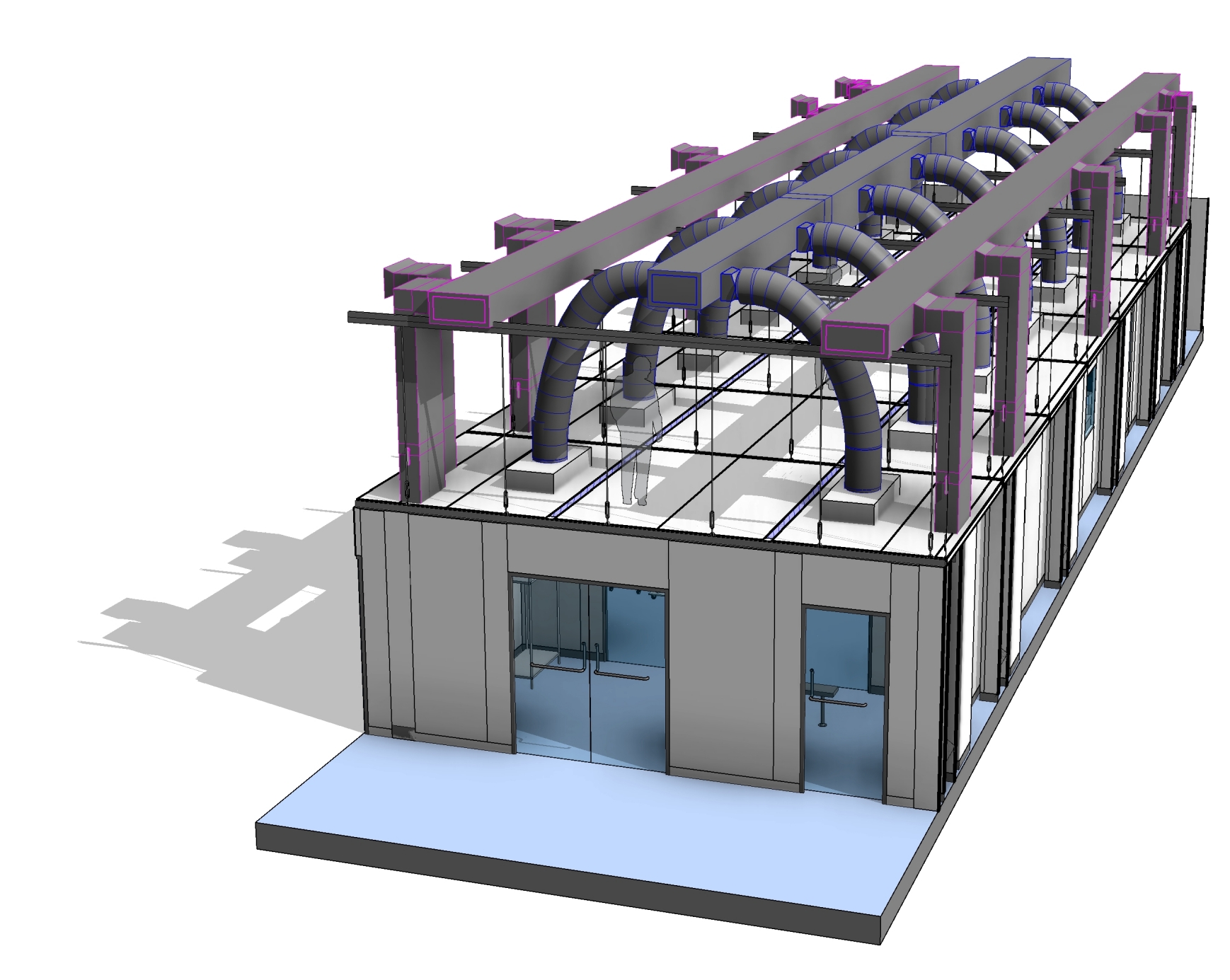

30 years ago, AES Clean Technology revolutionized the cleanroom with new modular design elements—cleanroom walls and cleanroom ceilings, as well as other industry-leading cleanroom components and HVAC supplies that you could use as building blocks to design custom cleanrooms to exacting specifications that meet all cGMP requirements.

Today, we remain the only cleanroom manufacturer in the United States that designs, builds, installs and commissions modular cleanrooms, and we will continue to do so to meet customer needs. Recently, however, we have begun to realize new customer needs, particular in the fast-paced production cell and gene therapies.

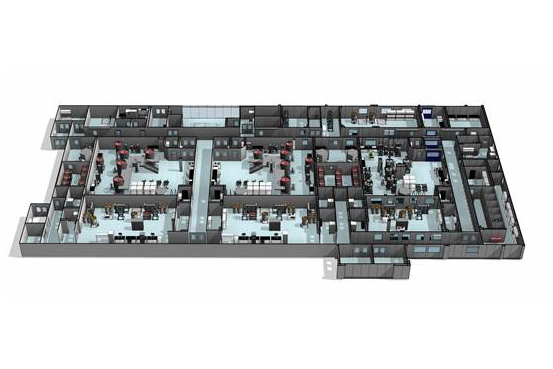

That’s why we have introduced the next generation cleanroom design with Faciliflex Express. We call the products 5k, 15k and 30k—representing 5,000, 15,000 and 30,000 square-foot cleanrooms, respectively.

Each step of therapeutic discovery and production already introduces risk into your product. Why would you build a new cleanroom facility that adds its own set of risks with every decision you need to make? Especially when you can leapfrog the entire process with a pre-engineered and proven all-in-one modular cleanroom solution.

Faciliflex Express, is a fully integrated product that reduces risk by packaging our proven design, manufacturing, HVAC, and installation expertise.

Reducing Risk across the Board

Yes, it feels odd referring to a cleanroom as a product. The truth is that we are “Productizing” what was a once a bespoke service. When done correctly, Productizing will greatly reduce risk for all involved and deliver superior value to you and your stakeholders. And at AES Clean Technology, we have the special mix of materials and experience to do it correctly the first time.

How do we reduce risk?

The Faciliflex Express products have set pricing; you will know what you will pay upfront, which eliminates risks related to cost overruns and the uncomfortable task of going back to investors for more funding.

Faciliflex Express also includes set timelines; you will know the lead times upfront, which lowers management costs and danger to your schedule.

By creating a standardized cleanroom product, we are also providing superior value for your investment. We are virtually eliminating unnecessary cleanroom design services from the equation, which often approach 10 percent of the cost of a new modular cleanroom facility. By removing Non-Recurring Engineering (NRE) costs, AES is providing relief to your bottom line.

Perhaps our biggest advantage is experience. Not everyone can deliver cleanroom infrastructure knowing that it will meet FDA and EMA requirements, as well as industry standards, such as ISO 14644 or the ISPE baseline guide.

Speed for the Sake of Patients and Industry

We firmly believe that we are not just building another cleanroom. We are removing a potential roadblock for new therapies. Sure, time is money. But time in pharmaceutical cleanroom and gene therapy cleanroom applications also represents human lives, particularly now. Our parents. Our kids. Our friends and neighbors.

Whatever part AES Clean Technology can play at speeding therapies to market safely brings all of us great satisfaction and peace of mind. Faciliflex Express is just the first of our new product lines.

Learn more and speak to an AES Clean Technology modular cleanroom expert today and see why we are considered the gold standard in the cleanroom industry.

About the Author

Royce Tourtillott is Western Regional Sales Manager for AES clean technology. His primary focus is on helping Clients develop and realize their business goals without compromising patient safety. With nearly 30 years of progressive experience, Royce has developed new technologies and successfully grown high-tech businesses serving the life science industry. He is inspired by those working to improve the human condition and seeks to equip others with the best tools available to fulfill this mission. As a recovering mechanical engineer and hopeless nerd, Royce enjoys spending free time tinkering at his electronics bench, enjoying the outdoors and traveling with his wife and daughter.