The AES method brings the most value with minimal drawbacks.

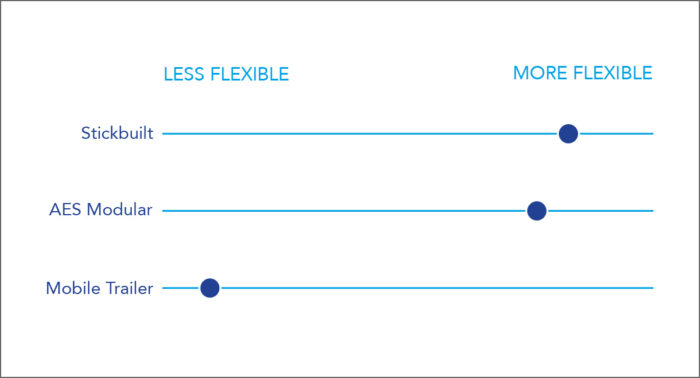

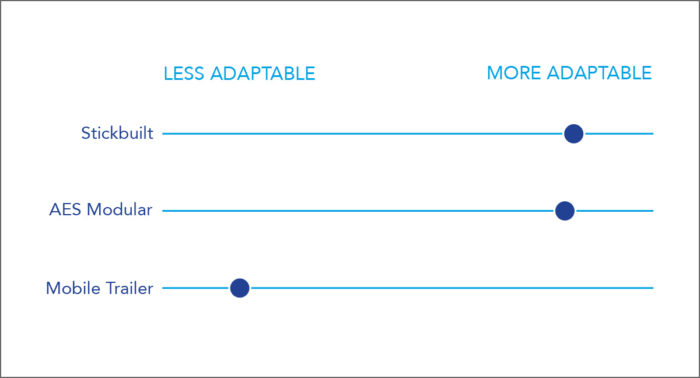

Below is a guide to show the relative strengths and weaknesses of various cleanroom construction methodologies that are being implemented within the marketplace. The AES solution represents a middle ground within a spectrum of project methodologies. We believe, and our clients can testify, that this solution captures the benefits of both ends of the spectrum while avoiding the associated risks with the extremes. That is why we deliberately chose pre-engineered modular construction as our tool for project execution.

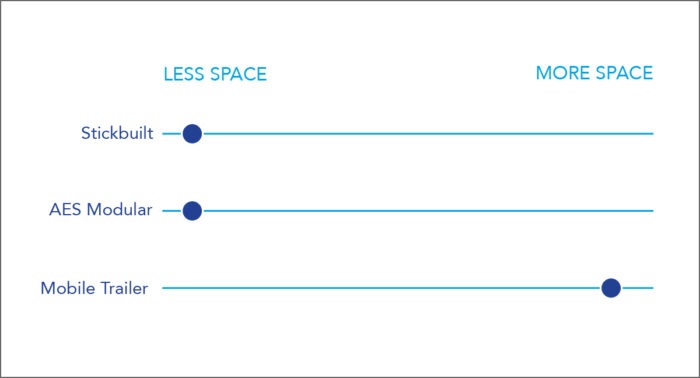

Space Requirements

Stick-built and AES Modular solutions are both limitless in flexibility, and designed not only to retrofit into existing spaces but also deployed into new facilities. The AES design team has over 35 years of design experience overcoming unique project challenges, including less than desirable space allocations, unique shapes, reduced overhead clearance – the list is endless.

AES modular construction occupies less space than traditional stick-built wall assemblies, and substantially less space than pre-fabricated building modules which require additional structural allocations and size limitations. With regard to mobile pre-fabricated building modules, these facilities require even more additional space to accommodate movement of the mobile modules within the facility, thereby resulting in larger facility footprints and the associated lifecycle costs.

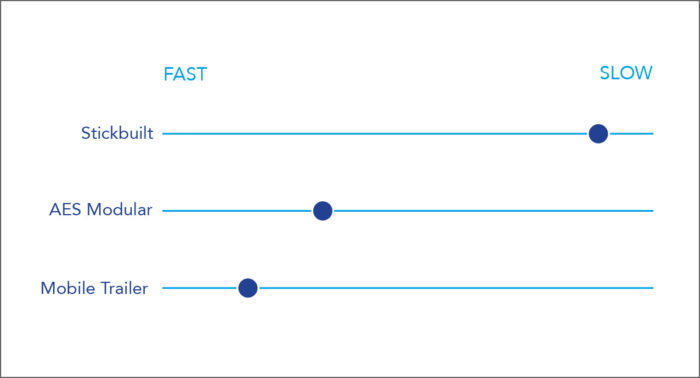

Time To Completion

Time is money. The faster you can have your facility running the better. AES intentionally chose the prefabricated cleanroom with onsite construction as our project delivery method.

Not only is it the fastest way to put up walls and ceilings, but because the construction is cleaner balancing and validation is faster too. AES has completed projects start to finish in as little as 16 weeks.

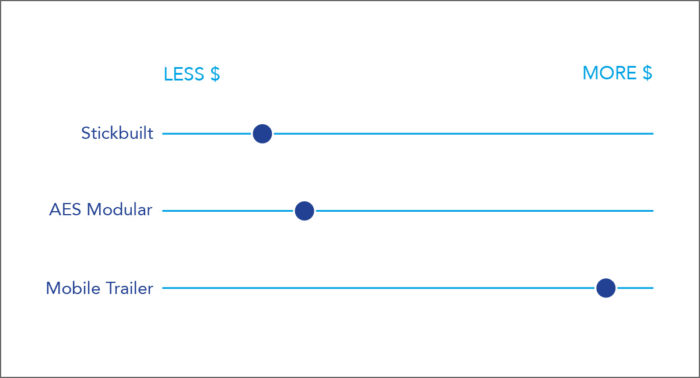

Cost

How do you evaluate the cost of a cleanroom project? Are you only looking at the initial capital expenditure at the time of ribbon cutting? Or do you evaluate the total cost of ownership? Do you evaluate the risks associated with cost predictability and performance predictability?

AES modular construction at the time of completion is only pennies on the dollar more expensive than stick-built construction. However, 3, 5, and 10 years beyond completion, the cost of ownership is substantially less than traditional stick-built facilities. The AES system is more robust and will reduce operational downtime due to reduced maintenance. The AES cleanroom system is seamless and minimizes places for microbial contamination. Not only will the facility cost less to own and operate, but the AES cleanroom will be beautiful and compliant due to with the state-of-the-art technology within it. And best of all, the cost and performance of the AES system is predictable.

Late Change Flexibility

Projects evolve, processes change, and where a project starts is not always where it ends up. Throughout the design, fabrication, and installation, AES can make rapid adaptations to keep your project on time and your performance objectives in focus.

Pre-engineered modular construction can be easily and cleanly reconfigured to address changes such as late arriving equipment, process evolution, or updated business drivers requiring facility flexibility. Now and in the future.

Guaranteed Performance

With AES Faciliflex program, our Integrated Project Delivery approach AES guarantees temperature, humidity, cleanliness, and pressurization.

We have never built a cleanroom that wasn’t validated and commissioned. Even our cleanrooms from 1985 are still operational. You want your project to go smoothly and AES can guarantee your cleanroom will work.

Host Building Adaptable

Both the AES modular solution and stick-built alternatives can be adapted into any host building environment.Those solutions are not limited by the size, shape, overhead clearance, or rigging pathway within the host building environment.

On the other hand, the mobile pre-fabricated building module may not be suitable within all host building environments because of the inherent limitations of spatial configuration and rigging limitations of a 3-dimension pre-fabricated assembly.

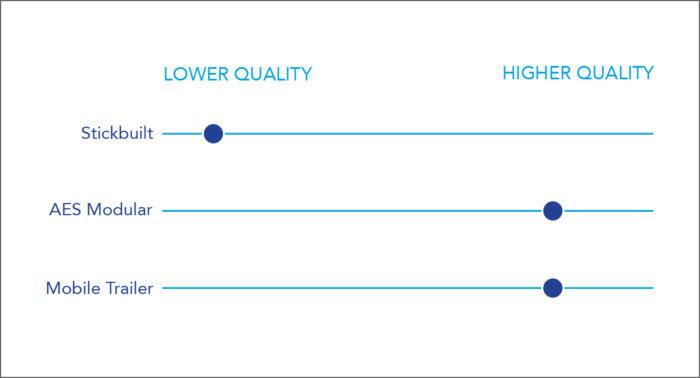

Quality

Modular construction takes finish details out of the hands of the mechanics in the field and puts them into the hands of the engineers in the factory environment. Controlled conditions on the manufacturing floor deliver repeatable, high quality results that far exceed those obtained through traditional stick-built finishes in the field. AES facilities are pre-engineered as a cleanroom system and are replicated all over the world with the same quality finishes and performance characteristics, regardless of location. AES choose the pre-engineered modular construction approach because it delivers predictable and repeatable performance while still allowing for ultimate customization and adaptability for the ever-changing environment of our clients’ businesses.

Our exclusive Construction Quality Plan (CQP) is a protocol that is generated expressly for your project, and is executed by our field team to document all aspects of the project’s lifecycle, including installation and operational verification. Most clients leverage this CQP to accelerate their validation activities and to reduce total project cost by minimizing the duplication of efforts between the cleanroom design/builder and the validation team.

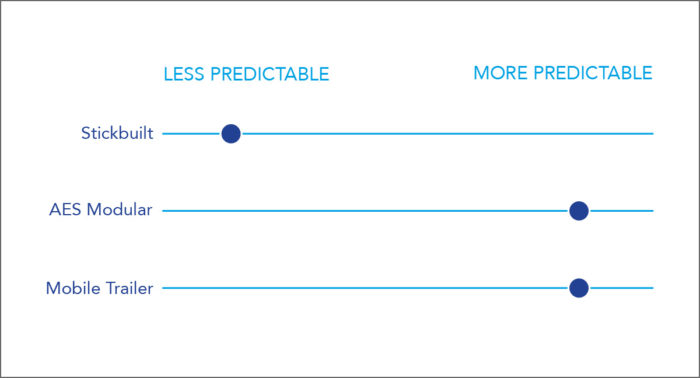

Predictability

Moving construction out of the field and into the factory allows for repeatability and predictability. AES chose this pre-engineered modular construction approach after witnessing its benefits first hand in the 1990’s.

This construction method delivers precision while still offering onsite adaptability and customization.

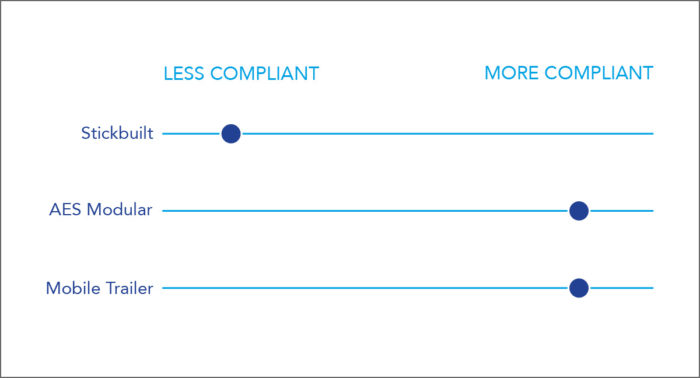

Compliance

Compliance does not allow for compromise.

The AES team are experts in delivering functional cleanroom facilities, and we take single point responsibility for delivering fully compliant projects.

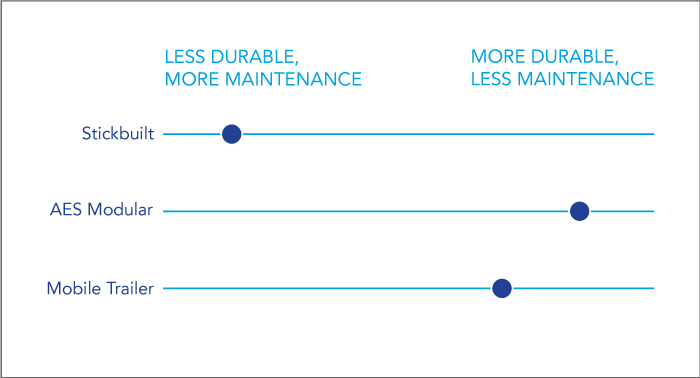

Maintenance/Durability

The demands placed on pharmaceutical and biotechnology cleanroom facilities is extraordinary, so these facilities must be robust and require minimal downtime for maintenance. AES has engineered our cleanroom facilities with flushness and cleanability as the cornerstone of everything we do. We provide seamless transitions from ceiling to wall, wall to wall, and wall to floor to accommodate the aggressive cleaning protocols of our most demanding pharma and bio clients. Our surface finishes were specifically chosen to provide compatibility with the sanitizing and decontaminating solutions that are used regularly within our facilities. There are lower cost materials available to construct modular systems such as painted metals, gypsum board assemblies, rock-wool or foam cores, but we will not use them.

Our focus is on total cost of ownership, not the lowest first cost material to construct a facility. We are a partner with our clients for life, so we invest in the right materials from the beginning – PVC surface finishes for chemical compatibility; aluminum structures for low flame spread and smoke development; honeycomb aluminum cores for strength, flexibility for change, and rejection of moisture; and PVC liquid welded joints for long-term integrity.

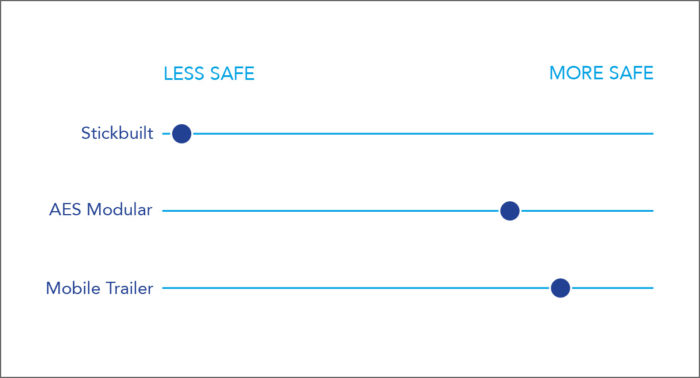

On Site Construction Safety

Safety data proves that removing processes from the field makes on-site construction safer. The method of pre-fabricated building modules offers the greatest reduction in site activities by shifting the majority of construction into the factory environment; however, not every project is suited for such a strategy. Pre-engineered modular construction, featuring flat packed panel systems that are locked into place at the project site, optimizes the use of factory resources and field personnel to create the cleanroom facility.

Our field teams consist of AES employees and skilled tradesmen who handle all aspects of the modular system installation. In contrast, traditional stick-built construction requires multiple disciplines such as framing, drywall, finishing, and coatings, all of which are additional personnel on the project site resulting in safety risk. With AES pre-engineered modular construction, we have one team that is present for the entire duration – less personnel, less dangerous activities, shorter duration – all resulting in less risk.

Life Cycle Issues

Your facility should help you prevent costly shutdowns. It should be operational with the least amount of maintenance, because when you aren’t making medicine you aren’t making money.

Will your process be the same in 5 years? If you are uncertain do you want your system to be capable of making changes while you are in operation and manufacturing? If the answer is yes, AES is the only system that can have a fully functioning cleanroom alongside of a new construction cleanroom. They can share the same wall, and our construction process will not interfere with your manufacturing.

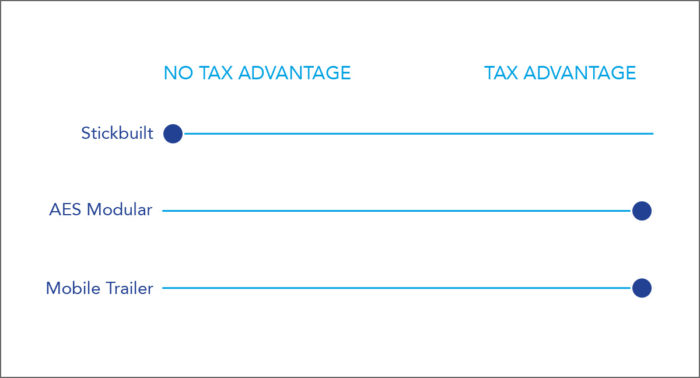

Tax Advantages

Modular cleanroom facilities can be considered capital equipment instead of capital improvements; therefore, they can be depreciated at an accelerated rate.

This results in tax savings for the client. In addition, under certain circumstances, initial tax burdens can be reduced as compared to traditional construction.