Accelerating Cleanroom Projects Through Modular, Off-Site Fabrication

AES Cleanroom Technology’s off-site manufacturing innovation revolutionizes how cleanrooms are built. We recognize that certain components are best fabricated in a controlled factory environment rather than through traditional on-site construction. Our engineered modular cleanroom components are manufactured off-site, delivering improved safety and quality at a reduced cost.

OSM can be leveraged for facilities that are operational during construction or expansion, off-site manufacturing shifts most fabrication to our controlled facility to drastically reduce noise, dust, and disruption inside a client’s building. This approach also allows us to have parallel workflows where we can site prep while building the necessary components in our facilities.

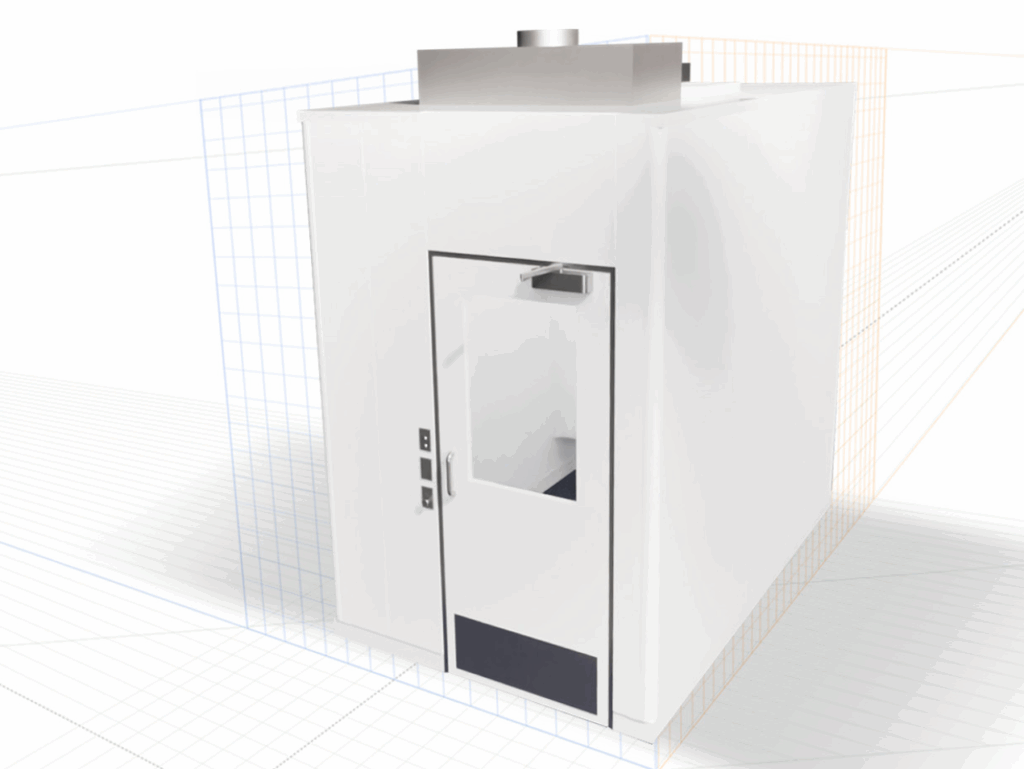

The CleanLock Module™ is our Off-Site Manufactured (OSM) prefabricated airlock, providing exceptional speed, quality, and contamination control. Its modular design integrates lighting, verified airflow, and interlocking PVC doors with magnetic locks and emergency systems. The 6’x10’x9’ module features 2” uPVC walls, HEPA supply filtration, and low wall returns for optimal cleanliness maintenance. It installs quickly, meets strict standards, improves safety, arrives ready for immediate modular cleanroom operation and avoids the hassle of conflicts with other trades in the building environment.

Omni Ascent™ is our off-site manufactured vertical utility solution delivering critical utilities exactly where needed, independent of wall placement. Built on the Omni Utility Raceway, it integrates electrical, process utilities, emergency systems, and data ports. Prefabricated, customizable, and relocatable, it installs in under a day, enhances safety, simplifies maintenance, and provides 360-degree equipment access while meeting ISO-compliant quality standards.

Our Omni™ Process Utility Raceway integrates up to six high-purity gas supplies into the vertical posts of our AES modular cleanrooms. Featuring 316L stainless steel piping, factory leak testing, and electro-polished components with FKM/FFKM seal, it supports gases like N₂, O₂, CO₂, Ar, Ne, He, and N₂O. This proprietary system reduces installation costs, simplifies maintenance, and delivers a precise, contamination-free gas distribution.

The Omni™ Electrical Utility Raceway integrates up to six power and data receptacles into the vertical posts of our AES modular cleanrooms. This patented, UL-listed system features pre-manufactured wiring, stainless steel gasketed cover plates, and separate channels for up to 300V power. Supporting up to twelve power and Ethernet connections, it reduces installation costs and time while providing customizable, code-compliant electrical access.

Working at AES Clean Technology has completely changed how I think about construction. We’re not just building walls, we’re building environments where life-saving therapies and cutting-edge technologies are developed. I’ve never worked anywhere that takes quality and safety seriously, and I’m proud to be part of a company where what I do every day actually makes a difference.

Complete Services, Solutions & Products